There are many products classified in this section of Automatic Paper Attaching. They are focused on folding all kinds of garments with Automatic Paper Attaching. Attention: The following garment are applied to this auto folding packing machine. Like, garment designed with many accesories, too thick coat,suits t shirts. Clothing Folding Machine, Hoodies Folding Machine, Automatic Clothes Folder, Automatic Clothes Machine SHENZHEN LINGCHUANG ZHUOYUE TECHNOLOGY CO., LTD , https://www.lcautosz.com

All machine include the following function:

1.Within the allowable value range, the folded length and width can be adjusted as you want.

2.The machine can automatically detect the length of garment, when the garment size is different, machine can intelligently identify and automatically fold according to the first folding length, so as to ensure the uniform folding length without changing the polybag. Clothes of different sizes can be folded into uniform sizes and packed into bags.

3.Machine will calculate the number of completed pieces automatically, and the alarm function for multiple

garments can be set up.

What is an Ore Pass in Mining?

# What Is an Ore Pass in Mining?

An ore pass is essentially a vertical or inclined mining shaft used to transport mined materials such as ore and waste from higher levels of a mine to lower ones. It serves as a convenient means to efficiently move materials and reduce the distance materials need to be hauled between different mine levels.

## Considerations for Constructing an Ore Pass

Ore passes utilize gravity to move materials downwards. There are primarily two methods for constructing ore passes: the drill-and-blast method and the mechanical method.

The drill-and-blast method involves drilling a hole at the desired location for the ore pass, followed by placing explosives to create the passage. Alternatively, the mechanical method uses a raise borer to excavate a circular tunnel between mine levels.

When building an ore pass, miners must take several factors into account:

- **Location:** Ore passes should connect with mining levels to ensure easy access for maintenance. Hang-ups, or blockages, are common issues in underground mining. The stress conditions and rock composition should be carefully evaluated when selecting a location. Placing an ore pass in weak host rock increases the risk of hang-ups. Ideally, ore passes should be located away from the mining face to preserve the mine's structural integrity.

- **Length:** Longer ore passes are more prone to wear and tear and are more expensive to construct. Typically, short ore passes ranging from 10 to 100 meters are built, though some can extend up to 300 meters in length.

- **Dimensions:** The size of the ore pass depends on the shape of the opening and the size of the materials that will pass through it.

- **Shape:** Ore passes can be square, rectangular, or circular. Those made with a raise borer are usually circular.

- **Orientation:** Ore passes can be either vertical or inclined based on the mine layout, the materials being transported, and the degree of fragmentation of the material.

- **Support:** Support structures like rebar and liners, such as shotcrete, are often used to reinforce ore passes.

Check out this video showing footage from Flyability's Elios drone inside an ore pass with a hang-up obstructing it:

## Types of Ore Pass Systems

In the mining industry, there are two primary types of ore pass systems: flow-through ore pass systems and full ore pass systems.

### Flow-Through Ore Pass System

In flow-through systems, ore is dropped into the ore pass and flows down to the draw point, where the ore is loaded onto loaders, conveyors, or rail cars and taken to an underground stockpile.

This system is ideal when the ore contains high levels of fines, or small particles, which can cause hang-ups if they settle. Since material is constantly moving, fines don't have a chance to settle, reducing the likelihood of blockages. Flow-through systems are also useful when the mill processes broken rock faster than the underground ore production in a full system. However, the continuous flow of material makes the ore pass more vulnerable to damage, requiring regular reinforcement, maintenance, or even costly redesigns.

### Full Ore Pass System

In a full ore pass system, a certain amount of ore is always kept in the ore pass at all times. This helps prevent degradation, rock failures, and mining-related seismic events. However, there is an increased risk of hang-ups because the material does not flow continuously. Fines can settle in the ore pass and oxidize, leading to blockages.

To manage these risks, the mill is continuously fed, and draw times from the ore pass are adjusted to maintain optimal material levels.

*A hang-up in an ore pass*

## Ore Pass Monitoring

Regular monitoring of the ore pass is essential to maintain its structural integrity, prevent mining-related seismic events, and avoid overfilling. Inspections typically focus on:

- Material levels

- Wall quality

- Liner quality

- Material control equipment

These inspections can be conducted manually or via drones specifically designed for mining. Neglecting to monitor an ore pass can lead to unexpected ore runs, hang-ups, equipment damage, structural instability, and even injuries or fatalities.

## Using Drones to Investigate Ore Pass Blockages

A blockage, or hang-up, in an ore pass can bring mining operations to a standstill. In 2023, workers at a major mining operation in Colorado faced a significant hang-up that completely blocked ore from descending the pass.

Initially, the hang-up was suspected to be close to the truck chutes where ore is collected. However, upon inspection, no visible obstruction was found. This indicated the blockage was located further up the raise, beyond direct visibility.

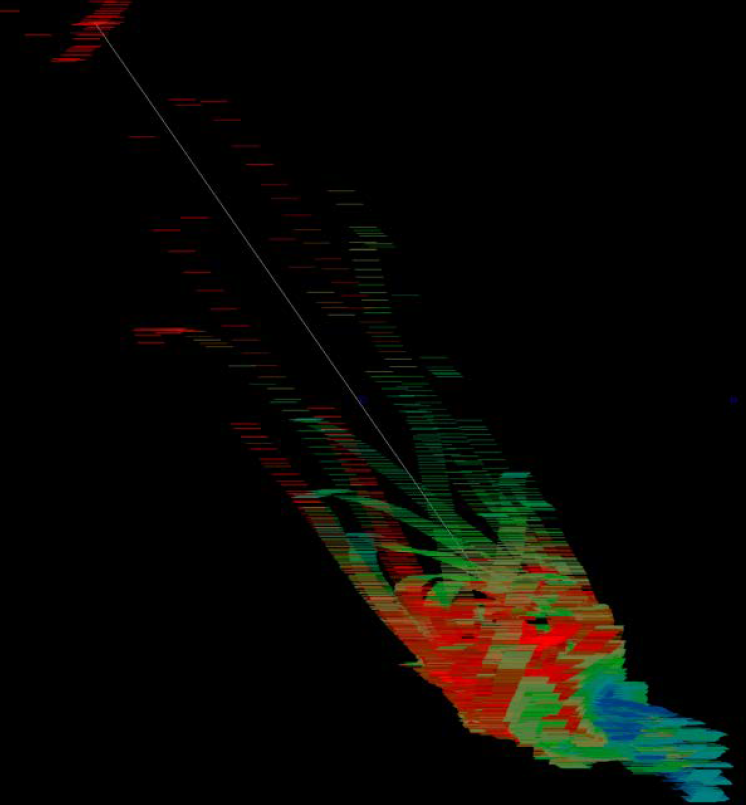

To locate the obstruction, workers first inserted a CMS scanner through a small access hole in the chute. The scanner provided a low-density point cloud of the raise, revealing that the hang-up was approximately 27.5 meters (90 feet) up the raise. Using this information, exploratory holes were drilled from a higher production level into the ore pass, and a small camera was sent in to pinpoint the exact location and nature of the blockage.

*CMS scan from an access hole in the chute*

Despite repeated attempts to clear the blockage by drilling and using small charges, only small fragments fell out, leaving the raise still obstructed. After two months of unsuccessful efforts, the area was deemed exhausted, and work ceased. The hang-up was never fully understood or resolved.

The solution came in the form of the Elios 3 drone, which proved invaluable in mining scenarios. The Elios 3 offers real-time visual feedback and a 3D Live Model on tablets, allowing operators to visualize the surroundings and navigate the drone effectively.

Within ten minutes of deploying the Elios 3, geolocational data on the 3D Live Map precisely identified the location of the blockage. This insight allowed for targeted intervention and resolution of the issue.

Learn more about how the data from the Elios 3 survey was utilized to investigate and address the ore pass hang-up.

---

Mining is a complex field requiring careful planning and execution. Tools like drones are revolutionizing safety and efficiency in this challenging environment.