An ore pass serves as a critical component in mining operations, acting as a vertical or inclined tunnel that facilitates the transfer of mined materials such as ore and waste rock from one level to another. This system is highly efficient because it leverages gravity to minimize hauling distances and streamline the movement of materials throughout the mine. As a result, ore passes play a vital role in reducing operational costs while maintaining productivity. Building an ore pass requires careful planning and execution to ensure its effectiveness and longevity. Two primary methods are commonly used for constructing ore passes: the drill-and-blast method and the mechanical method. In the drill-and-blast approach, miners drill a hole at the desired location and then detonate explosives to create the passageway. Conversely, the mechanical method employs a raise borer to excavate a circular passage between different mine levels. When designing an ore pass, several factors must be taken into account: Location: The ideal placement of an ore pass is where it intersects with mining levels. This arrangement allows miners to easily access and address any potential blockages, known as "hang-ups," within the system. Hang-ups are a frequent issue in underground mining due to stress conditions and the type of rock present. If an ore pass is situated in weak or unstable rock, it is more prone to hang-ups. Furthermore, ore passes should ideally be located away from the mining face to preserve the structural integrity of the mine. Length: Longer ore passes are more vulnerable to wear and tear and are generally more expensive to construct. Typically, shorter ore passes measuring between 10 and 100 meters are preferred, although some underground systems may extend up to 300 meters. Dimensions: The size of an ore pass is determined by the shape of the opening and the size of the materials being transported through it. Shape: Ore passes can be square, rectangular, or circular. Those created with a raise borer are typically circular in shape. Orientation: Depending on the mine layout and the type of material being transported, ore passes can be vertical or inclined. Vertical ore passes tend to cause more damage to the walls of the passageway. Support: Proper support is essential for the durability of ore passes. Common methods include reinforcing with rebar and applying shotcrete linings. Watch this video to see footage from Flyability's Elios drone capturing an ore pass with a hang-up obstructing it:  The mining industry utilizes two main types of ore pass systems: flow-through ore pass systems and full ore pass systems. In both systems, ore and waste are dumped into the ore pass and eventually reach the draw point, where the ore is transferred by loaders, conveyors, or rail cars to an underground stockpile. In flow-through systems, ore is poured into the ore pass and flows downward to the draw point. This system is particularly useful when dealing with ores that have high levels of fines (small particles), as continuous flow prevents these particles from settling and causing blockages. Flow-through systems are also employed when broken rock is processed through mills at rates exceeding those of underground ore production in full systems. However, due to the constant flow of material, flow-through systems are more prone to wear and tear, requiring regular reinforcement, maintenance, or even costly redesigns that can disrupt mining operations. In full ore pass systems, a certain volume of ore is always retained within the ore pass. This setup helps prevent degradation, rock failures, and mining-induced seismic events. However, this system carries a higher risk of hang-ups since material does not continuously flow through the pass. Fines tend to settle and oxidize, leading to blockages. Despite this risk, full ore pass systems are beneficial for maintaining steady mill feed rates. By adjusting draw times from the ore pass, operators can better manage material levels and avoid overfilling. Regular monitoring of ore passes is crucial to ensure their structural integrity, prevent seismic events, and avoid overfilling. Monitoring activities typically include checking material levels, assessing wall quality, evaluating liner condition, and inspecting material control equipment. These inspections, whether conducted manually or via drones, help prevent hang-ups and maintain mine safety. Neglecting to monitor ore passes can lead to undesirable material surges, hang-ups, and even catastrophic failures, jeopardizing equipment, infrastructure, and worker safety. A blockage, or hang-up, in an ore pass can bring mining operations to a standstill. In 2023, personnel at a major mining site in Colorado faced a significant hang-up that completely blocked the ore pass. The obstruction was so severe that no ore could pass through. Such blockages often occur near the truck chutes, where ore exits the raise and is loaded onto trucks. However, upon inspection, personnel found no visible signs of a hang-up in the chute. This indicated that the blockage was further up the raise, beyond direct visibility. To locate the blockage, workers initially inserted a CMS scanner through a small access hole in the chute. The scanner generated a low-density point cloud of the raise, revealing that the hang-up was approximately 27.5 meters (90 feet) up the raise. Armed with this information, they drilled exploratory holes of varying lengths—ranging from 12 to 21 meters (40 to 70 feet)—from a higher production level into the ore pass. They then fed a sewer camera into these holes to pinpoint the exact location and nature of the blockage. After identifying the blockage with the CMS scans, workers attempted to clear it by drilling holes and dropping small charges. While they managed to dislodge some debris, the raise remained clogged. These efforts continued for two months without success. Eventually, the area became exhausted, and upper management decided to abandon the section. Consequently, the problematic ore pass was left untouched, leaving unanswered questions about its exact condition and the nature of the blockage. The breakthrough came when the team turned to the Elios 3, a specialized drone for mining applications. Equipped with advanced technology, the Elios 3 offers pilots real-time visual feedback and a 3D Live Model on their tablets, enabling them to visualize both the immediate surroundings and the broader spatial context simultaneously. Within ten minutes, the Elios 3's geolocational data displayed the precise location of the hang-up on the 3D Live Map. This discovery marked a turning point in addressing the issue effectively. You can learn more about how the Elios 3's data was utilized to investigate and resolve the ore pass hang-up. Steam Required Shapping Machine

There are many products classified in this section of Tunnel Finisher With Virus Disinfection.

It is used for ironing, drying and Virus Disinfection of large-batch garments.

All kinds of chemical fiber, polyester cotton, wool polyester, wool, cotton, hemp and leather and other refractory fabrics.

The Tunnel Finisher with Virus Disinfection consists of 4 separate units and additional units may be added if required.

Uniform Clothes Finisher Ironing Machine,Steam Ironing Machine,Steam Ironing Machine For Laundry,Steam Machine For Clothes SHENZHEN LINGCHUANG ZHUOYUE TECHNOLOGY CO., LTD , https://www.lcautosz.comWhat Is an Ore Pass in Mining?

Key Considerations When Constructing an Ore Pass

Ore Pass System Types

Flow-Through Ore Pass System

Full Ore Pass System

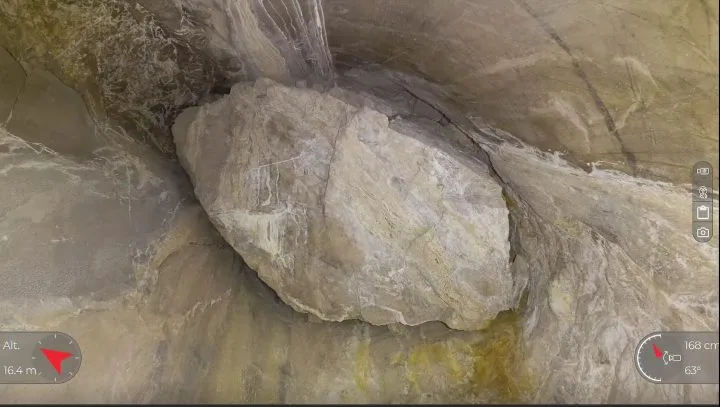

A hang-up in an ore pass

A hang-up in an ore passOre Pass Monitoring

Monitoring the material level in an ore passUsing Drones to Investigate Ore Pass Blockages

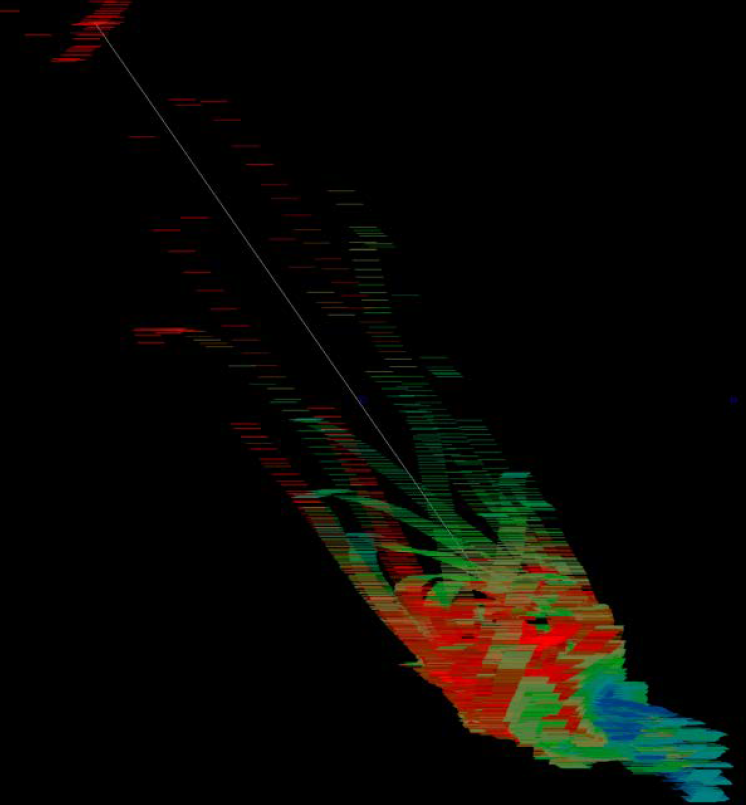

A CMS scan from an access hole in the chute

A CMS scan from an access hole in the chute