A general model, suitable for thick and thin clothes as well as pants. Machine realized the continuous operation of automatic folding and automatic packing of batches clothing, which improves the standardization and folding efficiency of clothing folding, greatly reducing labor costs, suitable for various types of clothing enterprises. Folding Machine For Pants,Clothes Folding Robot,Self Clothing Folding Machine,Textile Folding Equipment SHENZHEN LINGCHUANG ZHUOYUE TECHNOLOGY CO., LTD , https://www.lcautosz.com

How Mine Drones Are Improving Safety and Optimizing Mining

# Six Ways Mine Drones Are Transforming the Industry

In the world of mining, where safety is paramount and efficiency is key, mine drones have emerged as indispensable tools. These drones are not just consumer-grade gadgets; they are specially designed to withstand the harsh conditions of both surface and underground mining. Unlike typical drones that rely on GPS, mine drones can operate in environments where GPS signals are unavailable, making them uniquely suited for mining tasks.

A mine drone is essentially a drone tailored for specific mining needs, such as stockpile measurement, surveying, mapping, and inspections. These drones can even perform ultrasonic testing for thickness measurements. Mining is inherently risky, with worksite conditions often changing in an instant. While drones cannot eliminate all dangers, they can access areas that are unsafe for humans, providing crucial data while keeping personnel out of harm's way.

Take a look at this aerial footage from a surface coal mine:

The adoption of drone technology in mining has skyrocketed due to its ability to enhance data collection, boost safety, and cut operational costs. Here are six ways drones are revolutionizing the mining sector:

## 1. Volumetric Monitoring

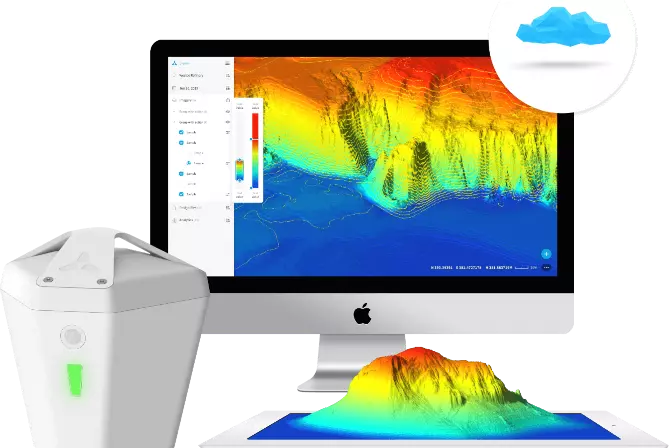

Volumetric measurement involves calculating the amount of material remaining in stockpiles of overburden, ore, or other mining resources. Given the immense size of stockpiles, getting accurate volume reports manually is a daunting task. However, incorporating mine drones allows for swift data collection that is both affordable and reliable. By tracking changes in stockpiles, businesses can avoid unnecessary waste and save significantly.

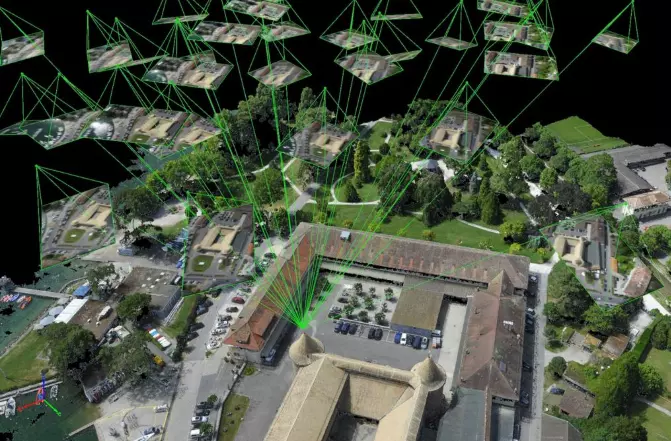

Advanced software processes drone-collected data to create 3D models. These models calculate volume by measuring from the base layer to the surface. Data can be sourced either through photogrammetry (using photos) or LiDAR scanning. Mine drones can also track how much material has been removed and estimate the amount of backfill needed for stopes. Over time, these models help analysts identify trends and changes.

## 2. Hazard Identification

Mining presents numerous hazards, from crumbling rocks to gas leaks and chemical byproducts. UAVs (Uncrewed Aerial Vehicles) are helping to mitigate these risks by replacing human inspectors. Remote monitoring enhances on-site safety, saving time and cutting operational costs.

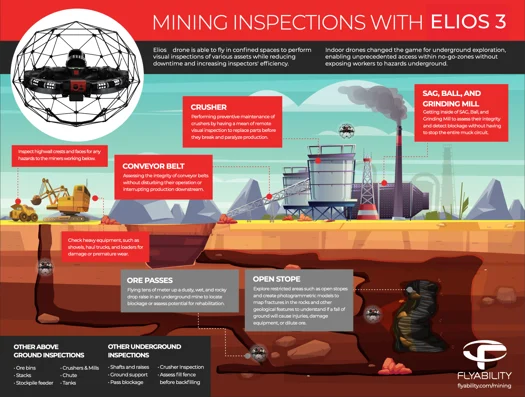

On the surface, drones monitor stockpile stability, detecting early warning signs of potential collapses. In underground mines, drones like the Elios 3 can navigate tight spaces filled with dust, water, and rocks. These drones equipped with sensors create 3D models to identify blockages, fractures, and other geological features.

## 3. Drilling and Blasting Assessment

Mine drones generate 3D models that serve multiple purposes, making them a cost-effective tool. Before drilling and blasting, a model can be created to serve as a historical record for analyzing previous work. Updated models help miners make informed decisions about potential hazards and evaluate the success of different blasting techniques. They also provide a remote safety check before entering a space.

## 4. Mine Monitoring and Planning

A mine consists of countless moving parts that require systematic analysis and adjustment to maximize efficiency and safety. Mine drones excel in several areas:

- **Haulage Road Design:** These roads transport materials from the worksite. Constant assessment of road conditions is vital due to heavy traffic. The data collected helps determine necessary infrastructure improvements.

- **Equipment Inspections:** Maintaining conveyor belts, crushers, and mills is crucial for reducing operational expenses and ensuring worker safety. Remote inspections via drones are cost-effective and safe tools for preventive maintenance.

- **Worksite Security:** Security drones are gaining popularity due to their quick deployment and ability to cover vast areas swiftly. They are especially beneficial in hazardous quarry and aggregate environments, offering protection and aiding emergency coordination.

- **Environmental Monitoring:** Drones monitor tailing dams, which contain hazardous chemicals. If unconfined, these chemicals could have devastating effects. Mine drones help maintain dam stability to prevent leaks or runoff.

## 5. Mine Development and Exploration

Historically, developing mining operations has been costly and perilous. Teams of miners would traverse unknown conditions to conduct stability analysis, surface mapping, and detect hazardous gases. Instead of sending people into inaccessible areas, drones can navigate tight spaces more safely and efficiently. This is particularly useful for investigating old parts of a mine. Drones mapping these areas keep people safe while providing critical data.

In underground mining, the Elios 3 stands out as the only drone capable of handling confined spaces with poor visibility, air quality, and signal interruptions.

## 6. Processing Plant Inspections

Drones are used in mining processing plants to inspect machinery without halting operations, ensuring profitability. Examples include checking wear plates on feeders and chutes, detecting cracks in machinery welds, performing ultrasonic thickness measurements on tanks, and assessing conveyor belt temperatures.

# Benefits of Drones in Mining

As drone technology advances, the advantages of UAVs in mining continue to grow. Here are some key benefits:

- Aerial data collection provides valuable insights for building models and assessments.

- Eliminates the need for manned aircraft for inspections and volumetric measurements.

- Frequent inspections highlight potential issues before they disrupt production.

- Reduces errors in stockpile measurements.

- Performs security patrols, saving time and money.

- Surveys are easy to conduct and repeatable.

- Reduces environmental impact by monitoring systems and threats.

- Mining drones are 30 times faster than ground-based inspections.

- Improved accuracy due to a large set of data points.

- Unique perspectives lead to data collection not possible with traditional methods.

- Advanced sensors capture high-resolution images and videos.

Watch the Elios inspect and map an obstructed ore pass:

# Best Indoor Mine Drone on the Market

Among the many capable drones, few match the functionality, durability, and beyond-line-of-sight capabilities of Flyability’s Elios 3.

The Elios 3 is built to keep humans safe while collecting data in previously inaccessible areas. Its spherical cage is collision-tolerant, helping pilots navigate dangerous, dark, and dusty locations. Dual thermal and 4K camera sensors, along with 10K lumen dust-proof lighting, allow the Elios 3 to collect all necessary visual data. Oblique lighting highlights textures and defects in mines.

With training, easy maintenance, and dedicated support, the Elios 3 is the best mine drone on the market.

**Flyability Elios 3 Specs / Features:**

- Dual Thermal/Camera Sensor: 12 megapixels HD live streaming

- Lighting: 10K lumen dust-proof lighting with oblique lighting

- LiDAR Mapping: Real-time 3D view of trajectory and environment

- Flight Time: 10 minutes

- Flight Speed: 6.5 m/s

- Transmission System: Beyond visual line-of-sight

- Modular Payloads: Use specialized LiDAR and ultrasonic thickness payloads

# Best Fixed Wing Outdoor Mine Drones on the Market

## WingtraOne GEN II

The WingtraOne GEN II offers maximized flying time, performance, and flexibility with its fixed-wing design. Covering 272 acres in one flight, it has a flight speed of 16 m/s (36 mph) and 59 minutes of flight time. Its vertical takeoff and landing (VTOL) system allows operation in any location.

**WingtraOne GEN II Specs / Features:**

- Camera Sensor: 42 megapixel Sony sensor

- Sensing Capabilities: Compatible with various sensors

- Flight Time: 59 minutes

- Flight Speed: 16 m/s (36 mph)

- Transmission System: Direct line-of-sight up to 10 km (6 miles)

## SenseFly eBeeX

The eBeeX is an autonomous drone requiring minimal intervention. Covering up to 1200 acres per flight, it can interchange cameras with nine optimized options. Its advanced eMotion software simplifies mission planning.

**SenseFly eBeeX Specs / Features:**

- Camera Sensor: Choose from 9 sensors, including aerial RGB, thermal, and multispectral imagery

- Sensing Capabilities: Compatible with various sensors

- Flight Time: 90 minutes

- Flight Speed: 30 m/s (68 mph)

- Transmission System: Flight range of 37 km (23 miles)

# Best Multicopter Outdoor Mine Drone on the Market

## DJI Phantom 4 RTK

The DJI Phantom 4 RTK is hard to beat for outdoor mining drones. Its 20-megapixel CMOS sensor with a mechanical shutter ensures accurate mapping.

**DJI Phantom 4 RTK Specs / Features:**

- Camera Sensor: 20 megapixels with 4K video resolution

- Flight Time: 30 minutes

- Flight Speed: 13 m/s (31 mph) in P-Mode / 16 m/s (36 mph) in A-Mode

- Transmission System: DJI OcuSync

# Best Mine Drone Software

## DroneDeploy

DroneDeploy’s mapping software for mining increases efficiency and accuracy while keeping teams safe.

**Top Features:**

- Stockpile Inventory Management

- Mine Planning and Excavation

- Safety and Compliance

- Centralized Operations Management

## Pix4D

Pix4D’s drone mapping and 3D modeling software reduces risks and boosts profitability.

**Top Features:**

- Forecast geotechnical hazards

- Accurate stockpile volume calculation

- Asset lifecycle management

- Generate high-resolution interactive 3D maps

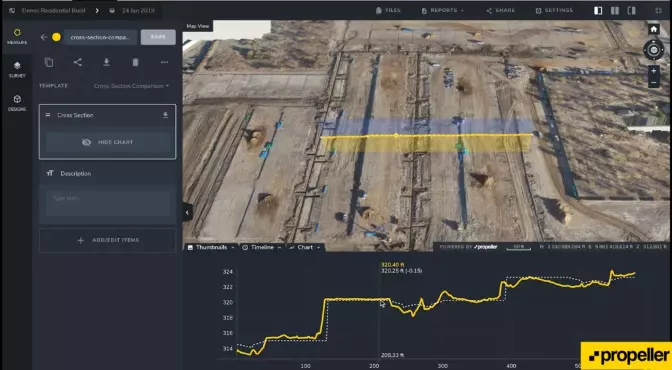

## Propeller

Propeller’s software captures high-accuracy data for 3D models accessible to the entire team.

**Top Features:**

- Quick and frequent drone surveys

- Complete project lifecycle documentation

- Simplified inventory management

- Collaboration and communication

## Skycatch

Skycatch’s software automates aerial data capture, processing, visualization, and analysis.

**Top Features:**

- Fastest time-to-data

- Eliminates GCPs for safer data capture

- Proven 5 cm accuracy across all axes

- Process offline or in the cloud

- Precise 3D models of vertical surfaces

# Mining Drone Case Studies

## Flyability Elios 2 — Inspection

**Application:** High-Altitude Underground Mining Inspection

**Mission:** Demonstrate the Elios 2’s ability to reduce costs and improve safety in an oxygen-depleted mine environment at 3 miles above sea level.

**Results:** The Volcan team conducted 40 flights inspecting chimneys, ore passes, ventilation tunnels, and stopes. All planned inspections were successful. The Elios 2 operated where no other drone could, enabling miners to focus on more critical tasks.

## Wingtra — Survey

**Application:** Mine/Quarry Monitoring and Operational Planning

**Mission:** Integrate a fixed-wing drone to reduce operational expenses compared to manned surveys.

**Results:** The Jellinbah Group saved significantly by using the WingtraOne. The fixed-wing platform eliminated inefficiencies of quadcopters, allowing on-demand surveys.

## SenseFly — Survey

**Application:** Quarry Monitoring and Operational Planning

**Mission:** Survey a 13.7 km² quarry in a single day.

**Results:** Using the eBeeX, the team covered the site in a few hours, taking over 6,000 high-resolution images. This was far quicker than the usual two-month process.

## DJI — Survey

**Application:** Quarry Drilling and Blasting

**Mission:** Use a customized drone solution to ensure safe, controlled, and cost-efficient blasting operations.

**Results:** The DJI Matrice 300 RTK drone and Zenmuse H20t cameras excelled in monitoring compliance, correcting lookout locations, and observing blind spots.

## DroneDeploy — Stockpile Measurement

**Application:** Stockpile Volumetry

**Mission:** Improve accuracy and reduce costs for Granite Construction.

**Results:** DroneDeploy achieved accuracy comparable to traditional methods in a fraction of the time.

---

The future of mining is here, and drones are leading the charge. From enhancing safety to boosting productivity, drones are reshaping the mining landscape.