Radiography is a technique that uses radiation to create images of objects or structures that are not visible to the naked eye. It's a powerful tool used in various fields, from medicine to industry, to examine the internal structure of materials without damaging them. In the medical field, radiography is commonly used to produce images of the human body, such as X-rays of bones, soft tissues, and organs. These images help doctors diagnose injuries, diseases, and other conditions. In industrial settings, radiography plays a crucial role in non-destructive testing (NDT). It allows inspectors to detect hidden flaws, cracks, or weaknesses in materials and structures without having to dismantle or destroy them. This makes it an essential tool for ensuring safety and quality in manufacturing and maintenance processes. This guide explores the many applications of industrial radiography across different industries. If you're interested in how radiography is used in medical contexts, we recommend checking out the FDA's resources on the topic. [Industrial radiography is one of several non-destructive testing methods used by inspectors. To learn more about NDT, check out this detailed guide.] [Note: Industrial radiography is sometimes referred to as industrial radiology.] Industrial radiography (IR) is a method that uses ionizing radiation—such as gamma rays or x-rays—to inspect the internal structure of materials and components. It’s widely used in industries where the integrity of equipment and materials is critical, such as aerospace, automotive, energy, and construction. The process involves directing radiation through an object and capturing the resulting image on a detector or film. The way the radiation interacts with the material provides valuable information about its internal condition, helping identify defects like cracks, voids, or corrosion. Industrial radiography has two main applications: Industries like automotive and aerospace rely heavily on radiography to test critical components. Similarly, sectors such as oil and gas, power generation, and construction use it to inspect boilers, pipes, and welding joints. [Related read: What Is a Dosimeter and Why Is It Important?] One of the key advantages of industrial radiography is that it is a non-destructive testing (NDT) method. This means it allows inspectors to examine materials without altering or damaging them, making it ideal for quality control and safety assessments. In contrast, destructive testing involves removing samples or modifying the material to analyze its properties. While these methods can provide accurate results, they are not always practical or cost-effective, especially when dealing with large or critical components. For example, testing for lead in paint using chemical reagents would permanently alter the sample, making it a destructive method. In contrast, radiography allows for repeated inspections without affecting the material being tested. While industrial radiography is a powerful inspection tool, it also carries significant risks if not handled properly. The radiation used in this process—whether from x-ray machines or radioactive sources—can be harmful to humans if exposed in high doses. According to industry reports, radiographers face a higher risk of radiation-related accidents compared to workers in other radiation-based fields. That’s why strict safety protocols, training, and regulatory oversight are essential in this profession. Compliance with safety regulations is not only a legal requirement but also a critical aspect of protecting both workers and the public from unnecessary exposure to radiation. Radiographic testing is a process that uses radiation to inspect the internal structure of a material. The basic steps involved are: The key benefit of radiographic testing is its ability to reveal hidden flaws that might otherwise go undetected. By analyzing the variations in radiation absorption, inspectors can determine the integrity of a material and make informed decisions about its safety and usability. The images produced are called radiographs. Historically, these were captured on film, but today most systems use digital detectors for faster and more accurate analysis. Industrial radiography relies on two primary types of radiation: x-rays and gamma rays. Each type of radiation has its own advantages and is suited to different applications. Gamma ray radiography uses radiation emitted from radioactive sources, such as isotopes like iridium-192 or cobalt-60. This type of equipment is compact and portable, making it ideal for use in confined spaces or remote locations. However, because the radiation source cannot be turned off, it requires careful handling and shielding to protect workers. Gamma ray equipment is often enclosed in protective housing to minimize exposure risks. X-ray equipment, on the other hand, is typically larger and requires a power source. It can be turned on and off, which makes it safer to use in environments where people are present. These systems are commonly used in factories, warehouses, and other large-scale industrial settings. They are well-suited for inspecting thick or complex structures, such as pressure vessels, pipelines, and welded joints. Due to the potential hazards associated with radiation, the use, ownership, and transportation of radiography equipment require proper licensing and adherence to strict safety regulations. If you're interested in a career in industrial radiography, there are clear steps you can take to enter the field. Most employers require at least a high school diploma and completion of a certified training program in industrial radiography. Some positions may also require additional certifications or experience in specific areas, such as radiation safety or advanced imaging techniques. An industrial radiographer is a professional who uses radiation to inspect materials, equipment, and structures for internal flaws or defects. Their work is critical in ensuring the safety and reliability of industrial assets. They often work with large, stationary equipment such as pipelines, storage tanks, and power plant components. Using x-ray or gamma ray technology, they generate images that reveal internal issues that are not visible to the naked eye. Throughout their work, industrial radiographers must follow strict safety protocols to minimize radiation exposure. This includes wearing protective gear, using shielding, and adhering to established procedures for handling and operating radiographic equipment. Jobs in industrial radiography are typically full-time and involve travel to job sites. Since the equipment and structures being inspected are often large and fixed in place, radiographers must visit the location to perform their work. According to ZipRecruiter, the average annual salary for an industrial radiographer in the U.S. is around $54,000. However, salaries can vary significantly based on factors such as location, experience, and level of certification. Some of the highest-paying jobs in the field are found in regions with strong industrial activity, such as the oil and gas sector or major manufacturing hubs. Additional certifications and specialized skills can also increase earning potential. As with many technical professions, the demand for skilled radiographers is expected to grow, particularly as industries continue to prioritize safety and quality assurance in their operations. Certification is a critical step for anyone looking to work in industrial radiography. In the U.S., certification requirements vary by state, but generally include hands-on training, a radiation safety course, and a written exam. Common certifications include:

Many states have their own certification programs that align with national standards. You can find more information about these programs on official government websites. As technology continues to advance, the future of industrial radiography looks promising. Innovations such as digital imaging and 3D modeling are already improving the accuracy and efficiency of inspections, and new tools like drones equipped with x-ray systems are beginning to emerge. Although drones are not yet widely used in industrial radiography, their potential in this field is growing. One example is the DroneX system developed by Pacific Imaging, which is designed to inspect power line components using x-ray technology. This drone is capable of reaching difficult-to-access areas, reducing the need for manual inspections and minimizing risks to workers. By using a drone, inspectors can collect data from high places or hazardous environments without putting themselves in danger. As drone technology becomes more advanced and affordable, we may see an increasing number of aerial systems equipped with radiographic capabilities. This could revolutionize the way inspections are conducted, making them faster, safer, and more efficient. Two Seats Electric Car,Handicapped Tricycle,Eec Electric Car,Disabled Tricycle YUMBOMOBILITY LTD , https://www.yumbomobility.comWhat Is Industrial Radiography Used For?

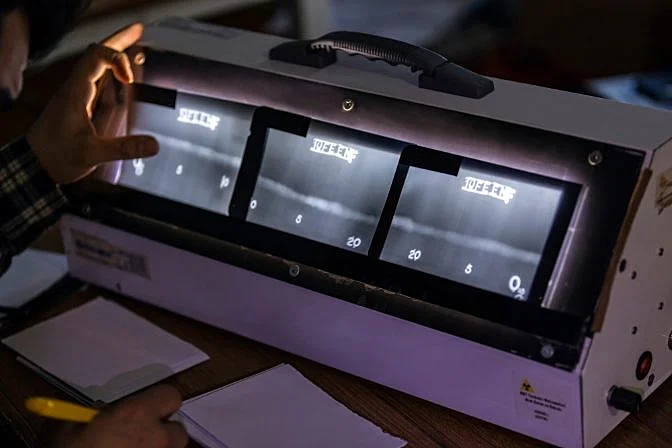

Radiographic testing used on a pipe

Radiographic testing used on a pipeIndustrial Radiography

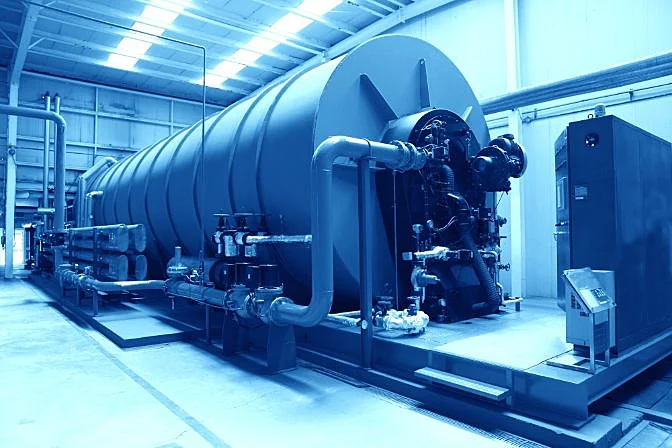

An industrial boiler

An industrial boilerNon-Destructive vs. Destructive Testing

A Note on Safety in Industrial Radiography

Radiographic Testing—How Does It Work?

Industrial Radiography Equipment

Gamma Rays in Industrial Radiography

X-Rays in Industrial Radiography

Industrial Radiographer Salary and Careers

What Is an Industrial Radiographer?

Radiographic testing used on a weld in an aboveground pipe

Radiographic testing used on a weld in an aboveground pipeWhat Does an Industrial Radiographer Salary Look Like?

Data provided by ZipRecruiter

Data provided by ZipRecruiterIndustrial Radiography Certification

Drones and Industrial Radiography

Photo credit: Pacific Imaging

Photo credit: Pacific Imaging