Radiography is a technique that uses radiation to create images of objects or structures that are not visible to the naked eye. It's a powerful tool for inspecting materials and systems in ways that traditional methods cannot achieve. In the medical field, radiography is most commonly associated with X-rays used to visualize bones, tissues, and internal organs. This helps doctors diagnose injuries, diseases, and other health conditions effectively. In industrial settings, radiography plays a crucial role in non-destructive testing (NDT). It allows inspectors to detect hidden flaws, cracks, or weaknesses within materials and structures without causing any damage. This makes it an essential tool for ensuring safety and quality in various industries. This guide will explore how industrial radiography is applied across different sectors, from manufacturing to energy production. If you're interested in understanding how radiography is used in healthcare, you can find more information on the FDA’s official website. [Industrial radiography is just one of many non-destructive testing methods. Discover more about NDT in this comprehensive guide.] [Note: Industrial radiography is also sometimes referred to as industrial radiology.] Industrial radiography (IR) is a method that uses radiation—such as gamma rays or X-rays—to examine the internal structure of materials and components. This technique is widely used in industries where the integrity of materials is critical to safety and performance. The two main types of radiation used in IR are X-rays and gamma rays. These forms of radiation can penetrate through various materials, allowing inspectors to analyze the internal condition of an object without physically altering it. There are two primary applications of industrial radiography: Manufacturers use IR to identify defects in raw materials or finished products before they are used in final assemblies. Inspectors use IR to check the structural integrity of equipment, pipelines, welds, and other critical infrastructure to ensure compliance with safety standards. Industries such as automotive, aerospace, and construction rely heavily on radiographic testing to maintain quality control. Similarly, power generation, oil and gas, and chemical processing industries depend on it for regular maintenance and safety checks. [Related read: What Is a Dosimeter and Why Is It Important?] One of the key advantages of industrial radiography is that it is a non-destructive testing (NDT) method. This means that the material being tested remains intact after the inspection, making it ideal for situations where the object cannot be damaged. In contrast, destructive testing involves removing samples or altering the material to assess its properties. While these methods can provide detailed information, they are often less practical for large-scale or ongoing inspections. For example, if you want to test for lead content in paint, you might use a chemical reagent that changes color upon contact. However, this method permanently alters the paint and is considered destructive. Industrial radiography involves the use of ionizing radiation, which can be harmful if not handled properly. The radiation comes from either a machine (like an X-ray device) or a radioactive source (like a gamma ray emitter). Because of the potential risks, strict safety protocols are in place to protect workers and the public. These include proper shielding, controlled access, and regular training for personnel involved in radiographic work. It's worth noting that industrial radiographers are among the highest-risk professions when it comes to radiation exposure, which is why their work requires extensive training and certification. Radiographic testing involves using radiation to inspect materials for internal flaws or inconsistencies. Here's a step-by-step overview of the process: Position the radiation source. An inspector directs X-rays or gamma rays toward the object under inspection. Place the detector. A film or digital detector is positioned on the opposite side of the object to capture the radiation passing through it. Capture the image. The detector records the amount of radiation that passes through the object, creating a visual representation of its internal structure. Analyze the results. Inspectors review the image to identify areas of concern, such as cracks, voids, or material thinning. These images, known as radiographs, can reveal hidden issues that would otherwise go undetected. Digital imaging has largely replaced traditional film-based methods, offering faster processing and better clarity. Industrial radiography relies on two main types of equipment: those that use X-rays and those that use gamma rays. Each has its own advantages and limitations depending on the application. Gamma ray equipment is typically smaller and more portable, making it ideal for use in confined spaces. It operates using a radioactive source, which does not require electricity. However, since the source is always emitting radiation, it must be enclosed in a protective shield to prevent exposure. X-ray equipment is generally larger and requires a power source. It can be turned on and off, which makes it safer to handle when not in use. However, due to the nature of the radiation, it still requires careful handling and proper licensing. In many countries, including the United States, the use, transport, and ownership of radiography equipment are strictly regulated by authorities like the Nuclear Regulatory Commission (NRC). If you're considering a career in industrial radiography, you'll need a solid foundation in technical skills and safety procedures. Here’s what you need to get started: A high school diploma or equivalent Completion of a certified training program in industrial radiography An industrial radiographer uses X-rays or gamma rays to inspect materials, components, and structures for internal flaws. Their work is vital in ensuring the safety and reliability of critical infrastructure and manufactured goods. They often work on large assets such as pipelines, pressure vessels, and welding joints. Their job involves setting up the equipment, capturing images, and analyzing the results for signs of damage or weakness. Throughout their work, industrial radiographers must follow strict safety guidelines to minimize radiation exposure. Jobs in this field are usually full-time and involve travel to different worksites, as the objects being inspected are often large and stationary. According to data from ZipRecruiter, the average annual salary for an industrial radiographer in the U.S. is approximately $54,000. However, salaries can vary significantly based on location, experience, and additional certifications. Those with advanced certifications or experience in multiple inspection techniques may earn significantly more. Additionally, working in high-demand regions or specialized industries can increase earning potential. Certification is required in most jurisdictions to practice industrial radiography. In the U.S., requirements vary by state but generally include hands-on training, radiation safety education, and passing a written exam. Common certifications include: RAM: Certification for working with radioactive materials X-RAY: Certification for operating X-ray equipment Both: Certification covering both radioactive materials and X-ray machines Many states have their own certification programs, and some are recognized nationally. You can find more information on the specific requirements in your area. While drones are not yet widely used in industrial radiography, there is growing interest in integrating them into the field. One notable example is the DroneX system developed by Pacific Imaging, which is equipped with an X-ray imaging unit. This drone is designed for inspecting overhead power lines, particularly conductor sleeves. It allows inspectors to gather detailed data without the need for manual climbs or bucket trucks, significantly improving safety and efficiency. As drone technology continues to advance, we may see more aerial platforms equipped with radiographic tools, expanding the possibilities of how and where industrial radiography can be conducted. Electric Tricycle,Canopy Cab Electric Scooter,Ce Certificated Electric Tricycle,Low Speed Electric Trcicyle YUMBOMOBILITY LTD , https://www.yumbomobility.comWhat Is Industrial Radiography Used For?

Radiographic testing used on a pipe

Radiographic testing used on a pipeIndustrial Radiography

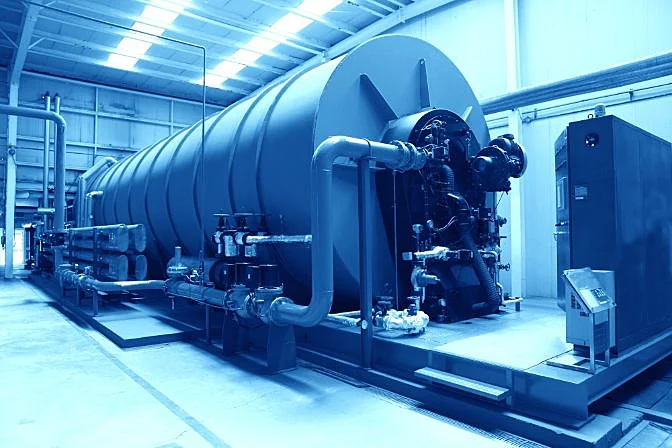

An industrial boiler

An industrial boilerNon-Destructive vs. Destructive Testing

A Note on Safety in Industrial Radiography

Radiographic Testing—How Does It Work?

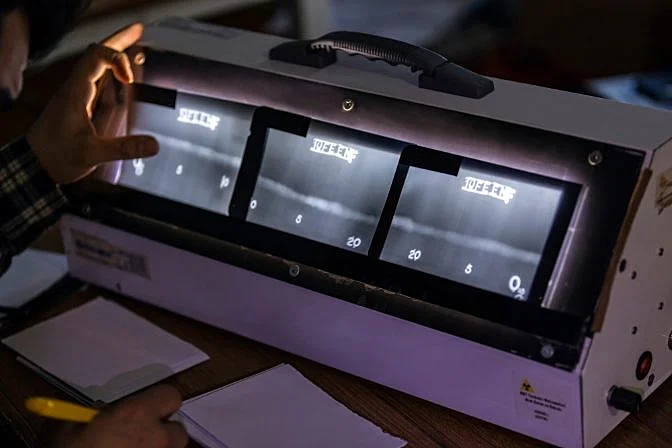

Industrial Radiography Equipment

Gamma Rays Industrial Uses & Equipment

X-Rays Industrial Uses & Equipment

Industrial Radiographer Salary and Careers

What Is an Industrial Radiographer?

Radiographic testing used on a weld in an aboveground pipe

Radiographic testing used on a weld in an aboveground pipeWhat Does an Industrial Radiographer Salary Look Like?

Data provided by ZipRecruiter

Data provided by ZipRecruiterIndustrial Radiography Certification

Drones and Industrial Radiography

Photo credit: Pacific Imaging

Photo credit: Pacific Imaging